|

Broad Ripple Random Ripplings

The news from Broad Ripple

Brought to you by The Broad Ripple Gazette

(Delivering the news since 2004, every two weeks)

|

| Brought to you by: |

|

|

|

|

|

|

Converted from paper version of the Broad Ripple Gazette (v13n09)

Everything you always wanted to know about the canal...Part Fifteen

posted: Apr. 29, 2016

For those readers just discovering this series on the canal now in its 15th part, I will explain why the canal is important and why the Gazette is doing this series. The dam that created the Central Canal was built on the White River in 1936 and the Town of Broad Ripple grew up around it. It is why we are here today. For years the canal has supplied the City of Indianapolis with 60% of its fresh water which is processed for our clean water supply.

We continue in this installment discussing where the canal ends, at the White River Treatment Plant located at 1220 Waterway Boulevard, just northwest of 16th and Martin Luther King Jr Street.

"One of the questions you asked," said Ed Malone, Director of Water Production for Citizens, "was what are those things [floating in the canal] with the solar panels...Those are what we call SolarBees."

"They are in the [canal] out here," I said to Mario Morone, Gazette writer, while pointing to the north end of the White River Treatment Plant.

One of the SolarBees just downstream from the skimmer and aqueduct, near the entrance to the White River Treatment Plant.

"Back by Pic-A-Part?" asked Edwin Morris, Operations and Maintenance Supervisor for Citizens. Pic-A-Part is the auto salvage yard between the treatment plant and the end of the canal.

"Yes," I replied.

Ed added, "Those structures sit out in the water and they are basically mixers."

"Yeah, I think I can see them spinning," I said.

"Yes, we feed carbon into the canal right south of the...right downstream of the aqueduct. So, you know where the aqueduct is?" said Ed.

I replied that I had been out on the aqueduct before to take pictures.

Ed continued, "Just downstream of the aqueduct, where Aqueduct Drive...if you took Aqueduct Drive directly up to the canal [from 16th Street], that is where we feed carbon. And when I say we feed carbon, as a part of our treatment process we use carbon to remove taste and odor, to remove atrazine, if we were to get hydrocarbons...in other words if a car went into the canal or somebody spilled oil or what not into the canal, we need to get it out of the water. So we use carbon to remove a lot of these things. We use what is called activated carbon to remove that. Granular activated carbon."

"We feed that into the canal just north (upstream) of where those SolarBees are. You'll see a mixer that's out there that's basically churning the water. That's where the carbon feed point is. And then these mixers (SolarBees), as the water continues to flow downstream from that application point, they keep [the granulated carbon] in suspension to increase the effectiveness of the carbon, so that we gain that whole distance as contact time so that we more effectively remove whatever's in the water."

I asked, "And then generally as it [travels down the canal] it just settles out to the bottom [of the canal]?"

Ed replied, "No. We settle it out in our treatment process in those settling basins [at the north end of the plant]."

"So it stays up in the water...," I followed up.

"It stays in suspension all the way through into the settling basin," said Ed.

"What did you call these things again?" I asked.

"They're called SolarBees," replied Ed. "B-E-E-S. Solar, then Bees. It's a brand manufacture. This is the only place we're currently using them. We're evaluating them on mixing in some of our tanks, too."

Edwin jumped in, "We just had some put in at Fall Creek in the mill race."

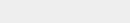

Ed recalled, "We did the same thing at Fall Creek. Fall Creek doesn't have a canal, but has a mill race. You know what I'm talking about?"

I answered that I did know about Fall Creek. The Fall Creek Treatment Plant is on the northwest corner of Fall Creek Boulevard and Keystone Avenue. The mill race Ed referred to is in the Fall Creek, which is across the street from the treatment plant. Historically there was a grist mill at this location on the Fall Creek. The mill race directed the rushing water into the mill to turn the wheel.

Ed continued, "Well, we still use the mill race as our intake to our treatment plant. So, Fall Creek, where the dam is, is very similar to the same way the canal works, only it's much smaller. So, the dam diverts water into our mill race and we take it through the treatment plant. And then we feed carbon in that mill race, no different than we do out here in the canal. We use the SolarBees in the mill race to keep the carbon in suspension there."

An aerial from around 1930 of the Fall Creek treatment plant (center) and the old mill (lower left). Keystone runs down the right side of the image. Fall Creek is at the bottom. The Nickel Plate RR tracks run diagonally in the upper left.

image courtesy of Indianapolis Water Company collection

Fall Creek Mill

image courtesy of Indianapolis Water Company collection

End of Part Fifteen

SolarBees

alan@broadripplegazette.com

|

|

|

| Brought to you by: |

|

|

|

| Brought to you by: |

|

|

|